Not known Facts About Dumpit Scotland

Dwelling clearances are a requirement For numerous persons and family members, no matter whether as a result of downsizing, moving dwelling, or handling the belongings of the deceased loved just one. In Edinburgh, Scotland, this sort of solutions are available, with numerous providers giving their expertise With this region. Between them, 1 outstanding name stands out: Dumpit Scotland.

Dumpit Scotland is a leading company of house clearance companies during the Edinburgh location. With their successful and professional technique, they may have earned a popularity for dependability and purchaser gratification. Their group makes a speciality of clearing Houses of all dimensions, from small apartments to huge estates, and so they take care of each individual element of the procedure with treatment and a spotlight to element.

Dwelling clearance is commonly a frightening endeavor for assets owners. It involves sorting through many years of accumulated possessions, selecting what to help keep, donate, or discard, and afterwards safely and securely eliminating and disposing of undesirable products. This process is usually too much to handle, both of those emotionally and bodily, Specifically in the course of currently stressful situations for instance relocating home or dealing with the estate of the deceased relative.

Dumpit Scotland understands the problems involved in household clearances and strives to generate the process as clean and tension-no cost as is possible for their purchasers. Their knowledgeable workforce is qualified to handle all sorts of possessions, which includes furniture, appliances, apparel, and private effects, with sensitivity and respect. They do the job proficiently to apparent the home in a very well timed method, letting clients to target other components of their lives.

One of many critical great things about employing an experienced household clearance company like Dumpit Scotland may be the satisfaction it offers. Rather then seeking to deal with The work by itself, that may be overwhelming and time-consuming, customers can have confidence in while in the abilities of properly trained gurus who'll cope with all the things from get started to complete. This incorporates not simply the Bodily labor of clearing the house but in addition the logistical facets like arranging transportation and disposal of items.

Dumpit Scotland features an extensive array of home clearance solutions to fulfill the desires of their clients. This features whole or partial clearances, the place they're able to clear a whole home or specific rooms as expected. They also give specialized services for clearing garages, attics, together with other challenging-to-reach parts. In addition, they might aid with the elimination of cumbersome items for example pianos, safes, and garden sheds.

Together with their standard property clearance services, Dumpit Scotland also offers added services to aid purchasers with the whole process of clearing and organizing their belongings. This contains packing and unpacking products and services for clients who're relocating household, as well as storage options for things that must be briefly saved over the changeover period of time. They may guide Along with the elimination of dangerous waste resources for instance asbestos or chemical compounds.

Dumpit Scotland can take delight in giving environmentally dependable property clearance companies. They can be devoted to recycling and reusing as much as feasible, making sure that goods which can be salvaged are provided a second life rather then ending up in landfill. They get the job done carefully with nearby charities and recycling facilities making sure that things are disposed of responsibly and Dumpit Scotland House Clearance Services ethically.

When choosing a household clearance firm, It is vital to decide on 1 which has a established track record of dependability and professionalism. Dumpit Scotland has constructed a robust track record during the Edinburgh location, owing to their dedication to shopper fulfillment as well as their dedication to delivering high-good quality services. No matter whether you might be dealing with a daunting household clearance job or simply need to have aid with decluttering and organizing your home, Dumpit Scotland is there to aid.

Helping The others Realize The Advantages Of Heat Interface Units

If you'd like more information on how to get; guide a support or fix for the product or service; sign up your warranty; or to connect with our United kingdom centered helpline, you have arrive at the correct place. Just give us a connect with and see how our award-successful Consumer Guidance group will let you.

Together with DHW generation through a plate heat exchanger, HIUs presenting Main shops to feed a warm water cylinder throughout the dwelling are accessible.

Our Literature library is made up of all the Heatrae Sadia and Megaflo Literature brochures, installation guides and consumer guides, available to watch and down load from 1 convenient to use, centralised location which includes an archive for discontinued solutions. Literature library Our manufacturing unit compliance requirements

Crown Professional Services (CCS) supports the public sector to attain maximum commercial value when procuring frequent goods and companies.

Your browser isn’t supported any longer. Update it to get the ideal YouTube knowledge and our latest functions. Find out more

One plate heat exchanger (PHEx) HIUs and HIUs without the need of PHEx Immediate heating and indirect domestic very hot water – This type of HIU maintains a plate heat exchanger for fast warm h2o but dispenses Along with the Place heating plate as well as the circulation pump and expansion vessel. Therefore the main water inside the developing passes from the radiators during the apartments, this has two most important pros, To start with it avoids the temperature drop (ordinarily about 50C) over the plate heat exchanger that makes lower temperature techniques utilizing heat pumps more economical.

Some tenants may well get freezing h2o, Other individuals could get scalding h2o off the faucet. This is often risky for business as disappointed tenants will inevitably go away.

Watchful thought in how Strength is sent to Each and every Area, and prioritising ongoing upkeep and checks, ensures the method creates the myriad of Added benefits it guarantees.

Ultimately, a heat interface unit is A necessary Section of any communal or district heating system. Applied most frequently in apartment blocks and flats, it is actually answerable for providing the new h2o and heating within a house via a community of pipes which can be linked to one central program.

The HIU is oblique so the primary heating circuit is hydraulically separated in the assets Area heating by a plate heat exchanger. The device operates only when DHW or space heating is needed ensuring Electricity effective Procedure.

This replaces the need for each dwelling to obtain a person boiler and allows get pleasure from producing Electricity inside a shared site, as opposed to on someone foundation.

The ICON HIU signifies the next era in HIU know-how, and we will probably be analyzing the capabilities and great things about ICON, inside our upcoming website posts, together with inside our number of webinars.

Mechanical wall mounted heat interface unit: Danfoss HIU service Completion codes for mechanical heat interface units Mechanical wall mounted heat interface unit Plurimod person modules

We also use third-occasion cookies that assist us analyze and know how you utilize this Web site. These cookies might be saved in your browser only along with your consent. You also have the option to opt-out of these cookies. But opting outside of some of these cookies could have an impact on your searching working experience.

Facts About Desalination Plant Manufacturer Revealed

Seawater Desalination with Reverse Osmosis Plant

All Reverse Osmosis vegetation are essentially Desalination Vegetation but desalination is remaining referred to sea water Generally.As sea h2o has extremely substantial TDS necessitates extremely large force to drive sea h2o via membranes which might be distinctive then brackish water membranes.

Reverse Osmosis Plant Particulars:

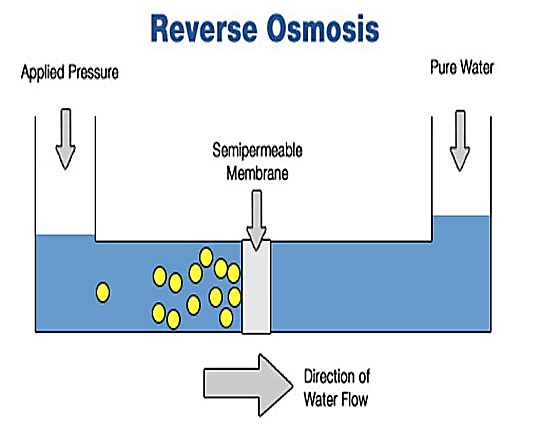

A reverse osmosis plant is really a manufacturing plant, wherever drinking water is purified and desalinated by forcing drinking water by way of a membrane, generally often known as a reverse osmosis system. H2o made by plant RO can be useful for quite a few uses like desalination, wastewater therapy, along with the reclamation of dissolved minerals.

RO Plant Description

A median drinking water RO plant procedure necessitates 6 KW hrs of electric power to desalinate one particular cubic meter of drinking water. Reverse osmosis water crops involves a number of pre-remedy strategies which includes softening, DE chlorination, and anti-scale remedy. Adhering to pre-remedy, higher amounts of tension deliver drinking water by way of a semi-permeable membrane, which retains all contaminants except h2o.

RO Plant Layout

To enhance the performance and life of the Reverse Osmosis plant, helpful pretreatment on the feed h2o is needed. Selection of the appropriate pretreatment will increase performance and membrane lifestyle by lessening:

Fouling

Scaling

Membrane Degradation

RO plant design and style is consisting of:

Determining pretreatment necessity of Reverse Osmosis Plant

If the feed water has traces of significant metals, it is highly advisable to dose some chlorine to alter the dissolved hefty metals to Bodily sort, the media filter will filter the majority of it in a very ro h2o purifier plant.

Reverse Osmosis Plant Choice of membrane

Membrane aspects are an important Portion of RO vegetation. The proteins (generally polyamide) that make-up membrane components fluctuate depending upon the ending clarity and intake water seawater or brackish water and so on

Waterman engineers Australia RO plant for seawater desalination

Waterman Engineers in Australia has created a Reverse Osmosis (RO) plant for seawater desalination, which delivers quite a few advantages over other desalination techniques. Here are a few crucial advantages of their RO plant:

Vitality Efficiency:

When compared with other desalination tactics like thermal distillation, RO calls for a lot less Electricity. Waterman Engineers' RO plant makes use of Superior membrane technological innovation, making it possible for it to function at reduce pressures and reduce overall Electrical power intake.

Environmental Effect:

RO generates much less brine discharge in comparison to thermal methods, cutting down the effect on maritime ecosystems. This aligns with Australia's center on environmental sustainability and conservation.

Large H2o Purity:

The RO course of action efficiently gets rid of salts, minerals, and impurities, making higher-high-quality freshwater that fulfills stringent ingesting water criteria. This reliability is important for offering Harmless and clear h2o to communities.

Modular Style:

Waterman Engineers' RO plant employs a modular structure, enabling for scalability and adaptability. This is especially advantageous for regions with different water needs, as modules might be included or adjusted accordingly.

Diminished Footprint:

RO crops generally Have a very scaled-down Actual physical footprint in comparison to thermal desalination plants, which regularly have to have considerable infrastructure for heating and cooling processes.

Fast Commence-Up and Shutdown:

RO vegetation is often begun and stopped relatively rapidly, enabling for greater responsiveness to transforming drinking water calls for and emergencies.

Decreased Chemical Utilization:

Contrary to Several other desalination procedures, RO involves less chemical compounds for operation and cleaning, reducing chemical-linked environmental problems.

Consistency in Efficiency:

The RO method is significantly less sensitive to feedwater high-quality fluctuations than other solutions, guaranteeing a more consistent general performance eventually.

Value-Efficiency:

Whilst Original expenditure fees is usually substantial, RO crops tend to possess decrease operational and upkeep expenses Over time compared to thermal solutions.

Reverse Osmosis (RO) can be a h2o purification approach that uses a partially permeable membrane to eliminate ions, unwanted molecules, and larger particles from ingesting h2o. By applying force to beat osmotic stress, it lets the passage of h2o molecules although rejecting contaminants, therefore producing thoroughly clean drinking water on a person side in the membrane and concentrated impurities on the opposite.

The working principle of a Reverse Osmosis (RO) plant requires making use of force to the saline Answer to power drinking water molecules by way of a semi-permeable membrane. This membrane lets only h2o to go though rejecting salts, contaminants, and impurities, causing purified h2o on the permeate side along with a concentrated Remedy of contaminants within the brine aspect.

The benefits of Reverse Osmosis contain making substantial-good quality, cleanse drinking water by eliminating contaminants, getting effective and cost-effective over time, demanding small chemical use, and staying adaptable to varied scales of operation from compact household programs to huge municipal plants.

RO crops have replaced Demineralisation (DM) plants simply because they usually provide a additional productive and cost-productive Resolution for water purification. RO devices Never Desalination Plant Manufacturer require the regeneration substances that resin-primarily based DM crops do and may take out a broader variety of contaminants, such as dissolved solids and microorganisms.

Waterman Engineers Australia probable makes use of Reverse Osmosis (RO) crops for seawater desalination by forcing seawater through a semi-permeable membrane to get rid of salt as well as other impurities. This process provides refreshing, potable h2o in the ocean, addressing drinking water scarcity and furnishing a sustainable supply for a variety of needs.

Considerations To Know About Designing OF SHELL AND TUBE Heat Exchangers for Floating Liquefied Natural Gas (FLNG)

Floating Liquefied Natural Gas (FLNG) production, liquefaction, and storage facilities have revolutionized the extraction and processing of natural gas from remote offshore reserves. These offshore platforms offer unprecedented flexibility and efficiency in the production of liquefied natural gas at sea. Among the crucial components of FLNG systems, heat exchangers play a pivotal role in the liquefaction process. This article explores the intricacies of heat exchanger design for FLNG, focusing on the challenges and requirements unique to these cutting-edge offshore installations, with a special emphasis on Waterman Engineers Australia's expertise in this field.

Understanding the FLNG Process: FLNG facilities essentially function as floating liquefaction plants, enabling the extraction, liquefaction, and storage of natural gas at sea. The process involves several vital steps:

- Production: Natural gas is extracted from offshore wells using production platforms or subsea systems.

- Gas Treatment: To ensure the purity of the gas and prevent interference with the liquefaction process (e.g., from carbon dioxide, water, and sulfur compounds), the extracted gas undergoes treatment.

- Liquefaction: The processed gas is cooled to extremely low temperatures, typically below -160 degrees Celsius (-256 degrees Fahrenheit), causing it to condense into liquefied natural gas (LNG). This liquefaction is necessary for efficient storage and transportation.

- Storage and Transportation: The produced LNG is stored in onboard tanks before being loaded onto carriers for transportation to markets.

The Role of Heat Exchangers in FLNG: Heat exchangers are indispensable components of FLNG facilities, primarily responsible for managing the heat transfer required to chill natural gas to the liquefaction stage. This critical task involves handling extremely low temperatures and ensuring efficient heat exchange across various process streams. Key considerations in designing heat exchangers for FLNG include:

- Cryogenic Conditions: FLNG operations entail working at cryogenic temperatures, posing a significant challenge for heat exchanger design. Selecting appropriate materials, such as aluminum alloys and stainless steels, is crucial to withstand these harsh conditions. Insulation and thermal management strategies are also employed to prevent heat loss and maintain the required low temperatures.

- Optimizing Liquefaction Efficiency: Achieving economic viability hinges on maximizing the efficiency of the liquefaction process. Modern heat exchanger topologies like spiral-wound or plate fin heat exchangers offer improved efficiency by providing a large surface area for heat exchange in a compact design. Computational fluid dynamics (CFD) simulations are essential for optimizing heat exchanger components.

- Compact Design for Limited Space: Space constraints are common in offshore FLNG operations. Hence, compact heat exchanger designs like plate and frame or brazed plate heat exchangers are preferred, as they offer high surface area-to-volume ratios, enabling efficient heat exchange in a confined space.

- Durability in Harsh Marine Environments: FLNG heat exchangers are exposed to severe maritime conditions, including high winds, salinity, and potential wave action. Ensuring longevity requires the use of corrosion-resistant materials and coatings, along with robust monitoring and maintenance systems to detect and address corrosion issues.

- Operational Flexibility: FLNG operations can experience variations in gas composition, flow rates, and environmental variables. Designing heat exchangers with customizable features, control systems, and the ability to adapt to changing conditions is essential for ensuring operational flexibility.

- Safety Compliance: FLNG plants are subject to stringent safety regulations. Heat exchangers must incorporate safety precautions to prevent incidents such as leaks or over pressurization. This includes emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves.

- Integration with Other Systems: Heat exchangers must seamlessly integrate with various interconnected systems within FLNG facilities, such as storage tanks, separators, and compressors. Collaborative design techniques and meticulous evaluation of the overall system structure are essential for efficient integration and optimal performance.

Waterman Engineers Australia's Expertise in Heat Exchanger Design for FLNG: Waterman Engineers Australia is at the forefront of engineering solutions, specializing in the design of heat exchangers tailored for FLNG applications. Their expertise has significantly contributed to optimizing FLNG plants while upholding the highest standards of excellence, sustainability, and safety.

- Cryogenic Expertise: Waterman Engineers Australia excels in addressing the challenges of cryogenic conditions in FLNG operations. Their team of experts possesses in-depth knowledge of designing heat exchangers capable of withstanding extremely low temperatures, a critical requirement for the liquefaction process. This expertise involves meticulous material selection, thermal management, and insulation techniques.

- Space-Efficient Designs: Recognizing the premium placed on space in FLNG operations, Waterman Engineers Australia employs creative and space-efficient design solutions. By leveraging advanced computational fluid dynamics (CFD) models and optimization methods, they strike a balance between effectiveness and compact size, ensuring that their heat exchangers meet space limitations without compromising performance.

- Safety Priority: Waterman Engineers Australia places safety at the forefront of their heat exchanger designs, fully understanding the stringent safety standards and regulations governing offshore activities. Their heat exchangers feature robust safety elements, including emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves, to maintain integrity and compliance.

- Operational Flexibility: Waterman Engineers Australia's heat exchangers are designed with a keen awareness of the dynamic nature of FLNG operations. They provide the necessary flexibility to adapt to fluctuations in gas composition, flow rates, and environmental factors. Their choice of corrosion-resistant materials and proactive maintenance techniques further underscores their commitment to durability.

- Collaborative Integration: Waterman Engineers Australia employs a collaborative design approach that ensures seamless integration of their heat exchangers into the broader FLNG system. By actively participating in the overall FLNG system's design, they optimize the entire facility, ensuring that their heat exchangers complement and enhance the overall efficiency and performance of the FLNG facility.

Conclusion: Waterman Engineers Australia's heat exchangers for FLNG demonstrate a profound understanding of the complexities involved in offshore liquefaction processes. Their leadership in providing state-of-the-art heat exchanger solutions for the evolving FLNG operating landscape is driven by their expertise in cryogenic conditions, commitment to safety, space-efficient design solutions, and collaborative integration strategies.

Choose Waterman Engineers Australia's Heat Exchangers for Floating Liquefied Natural Gas (FLNG) to elevate your industrial processes to new heights. Contact them today to explore how their solutions can optimize your heat transfer applications and contribute to the success of your FLNG operations. With their expertise, you can navigate the challenges of FLNG operations with confidence and efficiency.

FAQs (Frequently Asked Questions) - Heat Exchanger Design for FLNG by Waterman Engineers Australia

Q1: What is the significance of heat exchangers in FLNG facilities?

A1: Heat exchangers are critical components in FLNG facilities as they are responsible for managing the heat transfer necessary to liquefy natural gas. They play a vital role in cooling the gas to extremely low temperatures, enabling its conversion into liquefied natural gas (LNG) for storage and transportation.

Q2: How do heat exchangers in FLNG handle cryogenic conditions?

A2: Heat exchangers in FLNG must withstand cryogenic temperatures, which is a major challenge. Waterman Engineers Australia addresses this by carefully selecting materials that can resist extreme cold, such as aluminum alloys and stainless steels. Additionally, insulation and thermal management techniques are applied to prevent heat loss and maintain the required low temperatures.

Q3: What design optimizations are employed to enhance the efficiency of heat exchangers in FLNG?

A3: To improve efficiency, modern heat exchanger topologies like spiral-wound or plate fin heat exchangers are used to provide a larger surface area for heat exchange in a compact design. Computational fluid dynamics (CFD) simulations are employed to optimize the design and arrangement of heat exchanger components.

Q4: How does Waterman Engineers Australia address space limitations in FLNG installations?

A4: Recognizing the limited space on FLNG platforms, Waterman Engineers Australia employs creative and space-efficient design solutions. They utilize advanced computational models and optimization methods to ensure that heat exchangers are both effective and compact, allowing them to fit within the space constraints without sacrificing performance.

Q5: What safety measures are incorporated into the design of heat exchangers for FLNG?

A5: Safety is a top priority in FLNG operations. Waterman Engineers Australia's heat exchangers are equipped with robust safety elements, including emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves. These features are essential to prevent incidents like leaks or over pressurization.

Q6: How do Waterman Engineers Australia's heat exchangers adapt to the dynamic nature of FLNG operations?

A6: FLNG operations can experience variations in gas composition, flow rates, and environmental factors. Waterman Engineers Australia designs heat exchangers with customizable features, control systems, and the ability to adapt to changing conditions. This operational flexibility ensures optimal performance in the ever-changing offshore environment.

Q7: How does Waterman Engineers Australia ensure the longevity of their heat exchangers in harsh marine environments?

A7: Waterman Engineers Australia focuses on durability by using corrosion-resistant materials and coatings. Additionally, they implement strong maintenance and monitoring systems to detect and address potential corrosion issues, ensuring the extended life of their heat exchangers in challenging maritime conditions.

Q8: How does the collaborative integration approach benefit the performance of FLNG facilities?

A8: Waterman Engineers Australia actively participates in the design of the overall FLNG system, ensuring that their heat Designing OF SHELL AND TUBE Heat Exchangers for Floating Liquefied Natural Gas (FLNG) exchangers seamlessly integrate with other interconnected systems like storage tanks, separators, and compressors. This collaborative approach optimizes the entire facility, enhancing efficiency and performance.

Q9: Why should I choose Waterman Engineers Australia's heat exchangers for my FLNG operations?

A9: Waterman Engineers Australia's heat exchangers are designed with a deep understanding of the intricacies of FLNG operations. Their expertise in cryogenic conditions, commitment to safety, space-efficient designs, and collaborative integration strategies make them a reliable choice to optimize your heat transfer applications and contribute to the success of your FLNG operations.

Q10: How can I get in touch with Waterman Engineers Australia to discuss their heat exchanger solutions?

A10: You can contact Waterman Engineers Australia to explore their heat exchanger solutions and discuss your specific needs by visiting their website or reaching out to their dedicated team of professionals. They will be happy to assist you in enhancing the efficiency and safety of your FLNG operations.